Login

our business

- Check the boredhole and bentonite slurry (or polyme) before testing.

- Locate the KODEN machine by crane.

- Input data.

- Place the winch unit over the top of boredhole or on the steel casing. Position the sensor at the center of the hole.

- Lower the sensor into bentonite slurry. Hole the sensor at depth approximately 1.00 to 1.50m for initial calibration.

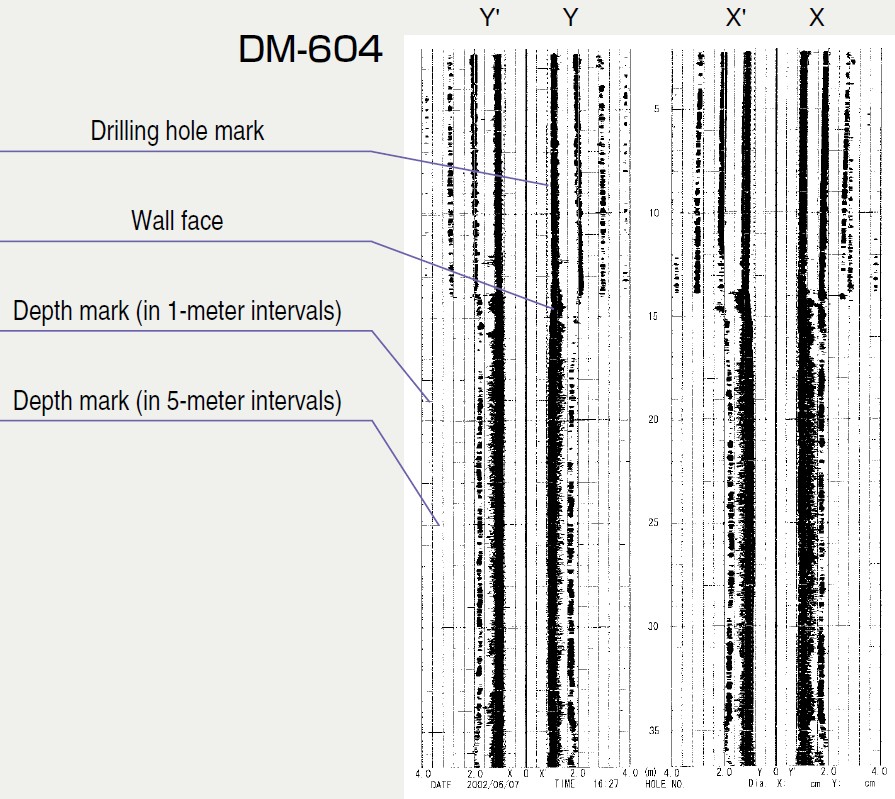

- Apter calibrations, restore the sensor to the starting position and perform the test. The tests are carried out in downward monitoring and upward monitoring. Boredhole profile along 2 perpendicular axes are printed out immediately.

- Submit testing reports at the site.

- Testing reports are printed by the KODEN machine.

- Conclusion and recommendation (Location/depth where abnormality occurs such as reduction in diameter, or collapsed wall)

|

The purpose of the method is check some parametters of boredhole: size (diameter and depth), shape of the drilled hole (vertical level, tilt,...). Testing method: KODEN test utilizes the principle of ultrasonic wave travel from sensor to the wall of boredhole and reflect to the sensor through the bentonite slurry as a media. Wave travelling time varies with size of the hole so it can be interpreted to reflect characteristics of the hole accordingly. Testing procedure: According to the special procedures of each device manufacturer or according to its own standards by Design consultant regulations Testing step:  |

Related Products

Buy now

KODEN Test

0đ

Quantity: 1

CUSTOMER INFORMATION

SHIPPING ADDRESS

PAYMENTS

YOUR ORDER INFORMATION

KODEN Test

0đ

Quantity: 1

Subtotal

CUSTOMER INFORMATION

- Full name:

- Phone:

- Email:

SHIPPING ADDRESS

- Address:

- Country / district:

- Province / city:

- Shipping costs:

- Note:

PAYMENTS