Login

our business

- Attach 2 accelerometers and 2 strain transducers symmetrically to pile shaft at the level of 2 pile diameters from pile head.

- Enter the parameters, test sensors. Adjust the sensors if necessary.

- Drive 2 - 5 blows to the pile head using a heavy hammer.

- Check the signal quality, re-drive if the signals are not good.

- Turn off the equipment and move to other pile.

- Project name and location/ The owner, designer, piling contractor and the tester.

- Tested pile records.

- Summary table of test results.

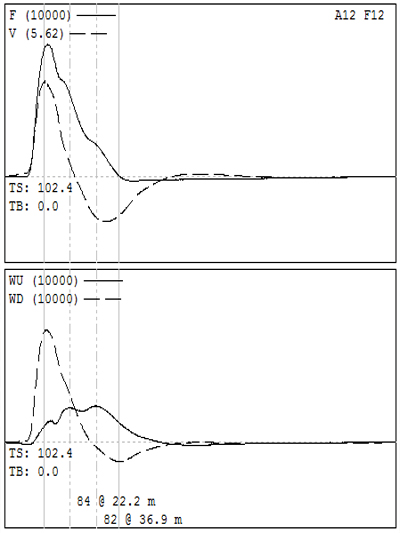

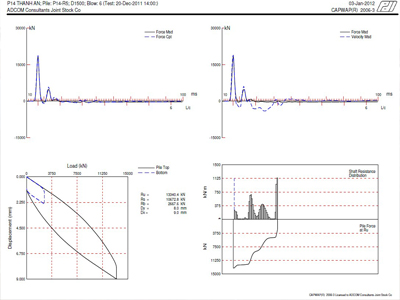

- Graphs of forces, velocity, bearing capacity, energy to time.

- Simulate load-settlement relationship graph and computing tables for CAPWAP analysis.

- Conclusion and comments.

|

Purpose of the test: determine bearing capacity of bored piles/pre-cast pile/barrette... based on the measurement of velocity and forces at pile head using CASE method and/or CAPWAP. Testing method: Method used is to measure the velocity and stress by accelerometers and strain transducers under the impact of hammer, which is enough to drive the test pile 2-3mm down Testing procedure: arcordance to testing standard: ASTM D4945 or equivalent standards of other countries and Designer 's specifications. Testing steps: Testing report: |

Related Products

Buy now

Dynamic load test

0đ

Quantity: 1

CUSTOMER INFORMATION

SHIPPING ADDRESS

PAYMENTS

YOUR ORDER INFORMATION

Dynamic load test

0đ

Quantity: 1

Subtotal

CUSTOMER INFORMATION

- Full name:

- Phone:

- Email:

SHIPPING ADDRESS

- Address:

- Country / district:

- Province / city:

- Shipping costs:

- Note:

PAYMENTS